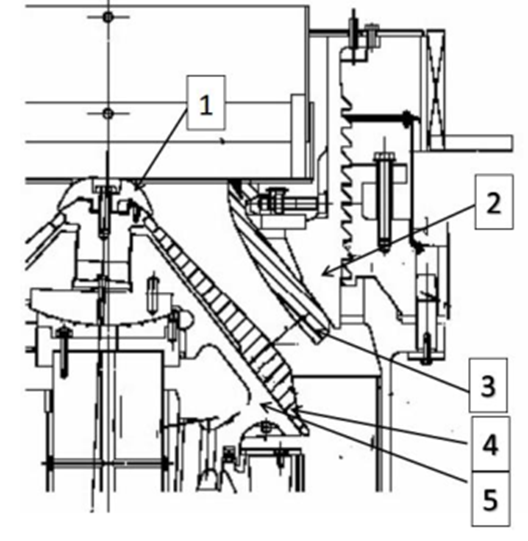

A certain plant uses HP5 cone crusher for medium and fine crushing of ore dressing and crushing. Its structure and installation of the moving cone liner are as shown in the following figure:

In the picture below: 1 material distribution plate; 2 fixed cone; 3 fixed cone lining plate; 4 moving cone lining plate; 5 moving cone

01 Failure problem: The hardness of the ore in this plant is high (f=12-16). The newly installed moving cone liner can be used for half a month according to the service life requirements to crush 100,000 tons of ore. However, the site environment is harsh and dusty. Large, the belt operator supervision is not in place, the iron removal effect of the permanent magnet iron remover is not very good, iron often passes through during crushing, in addition, the installation of the moving cone liner is not tight, the cutting ring is not welded firmly, and the locking screw is not tight. Defects such as fastening in place and incorrect installation of the liner can cause the movable cone liner to easily break and fail during use, resulting in low cone crushing efficiency, increased production costs, and unnecessary cost consumption.

02 Failure cause analysis

During the cone crushing process, the crushing cavity is filled with lump ore with an ore particle size of 60-120 mm. The moving cone lining plate performs both slow rotation and transverse stroke motion, which acts on the crushing load on the lining plate. It is relatively large, with both circumferential load and radial load. Therefore, if there are the following defects during the installation or crushing process of the liner, it is easy to cause the failure of the moving cone liner, such as: liner breakage and failure, locking screws loosening and falling off, etc.

(1) The liner is not leveled and adjusted when installed, and is biased to one side. When broken, the load around the liner is uneven, and it is easy to break, loosen and fail.

(2) When installing the lining plate, the contact surface between the moving cone and the moving cone lining plate is not clean and the fit is not tight. The lining plate will become loose during crushing and the crushing will fail.

(3) When the liner is installed, the locking bolts are not tightened in place and the tightening strength is not enough. During the crushing process, the liner becomes loose and easy to break and fail.

(4) When the liner is installed, the upper compression cutting ring is not welded firmly, or the weld is worn and opened during the crushing process, and the liner becomes loose and easy to break and fail.

(5) Iron blocks often enter during the crushing process. The hardness of the iron blocks increases and the crushing load increases. When the rated value of the liner is exceeded, the liner will easily break and fail.

Actions taken

Based on the above analysis, the following corresponding measures are taken:

(1) Level and adjust the liner when installing so that the load around the liner is evenly balanced during crushing.

(2) When installing the lining plate, thoroughly clean the mating surfaces of the moving cone and the moving cone lining plate to ensure tight contact and fit.

(3) When installing the lining plate, the locking bolts are tightened in place and the tightening strength is sufficient so that the lining plate will not loosen easily during the crushing process.

(4) When the liner is installed, the upper compression cutting ring and the liner are welded firmly. During the crushing process, check whether the weld is open once every shift. If it is, re-weld firmly.

(5) In order to prevent iron pieces from frequently entering the crushing cavity during the crushing process, a reasonable electromagnetic iron remover is installed at the head of the feed belt to remove iron pieces and balance the load of the lining plate evenly during the crushing process.

Processing effect

After the lining board is properly installed and the electromagnetic iron remover is installed on the head of the feeding belt conveyor, after production crushing inspection, the lining board will not break if iron does not enter. It can be used stably for half a month, crushing 100,000 tons of ore, and the service life is improved. Production costs are significantly reduced, ensuring the completion of production tasks. After careful observation and analysis by professionals at the site, the problem was discovered and the cause was identified. It is relatively easy to deal with the failure of the cone crushing cone liner being loose and prone to breakage and failure.